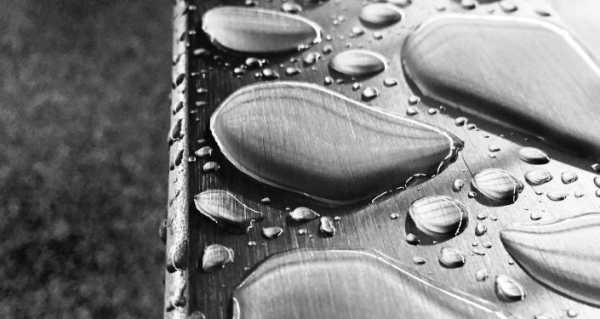

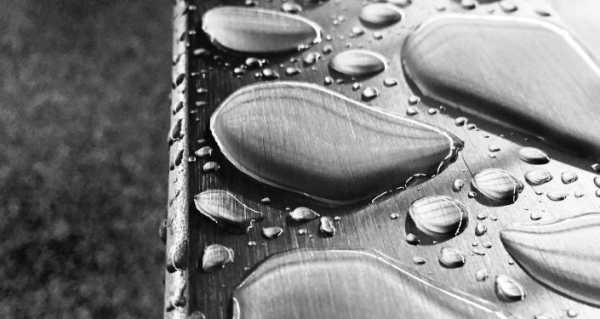

New alloys created by scientists from the National University of Science and Technology “MISiS” (NUST MISIS) in cooperation with LG Electronics may reduce the weight of heat sink and heat dissipation systems in electric cars and consumer electronics by a third.

According to experts, with the development of electronics, the problem of efficient heat dissipation becomes more and more acute – as technology performance increases, so does heat dissipation. Reducing the temperature has a direct impact on extending the lifecycle of devices. This is particularly important for household appliances, electric cars, and LED panels.

Scientists at NUST MISIS, in cooperation with LG Electronics, have created new high-thermal conductivity magnesium alloys that are more reliable and less expensive than their analogues, enabling them to significantly reduce the weight of devices.

One of the challenges in operating magnesium alloys, as the scientists noted, is their ability to ignite in the air. By adding calcium and yttrium, scientists have been able to significantly increase ignition temperature, making the new materials suitable for use in a variety of applications without restriction.

The results of this work allowed LG Electronics to register patents for the high thermal conductivity magnesium alloy (Mg-Si-Zn-Ca) developed at NUST MISIS and a heat sink based on this alloy in the US, the EU, South Korea, and China.

The research team is currently working on new magnesium-based alloy compositions that offer low cost and high thermal conductivity as well as high strength and corrosion resistance.

Sourse: sputniknews.com

0.00 (0%) 0 votes